Subsurface Safety Valve

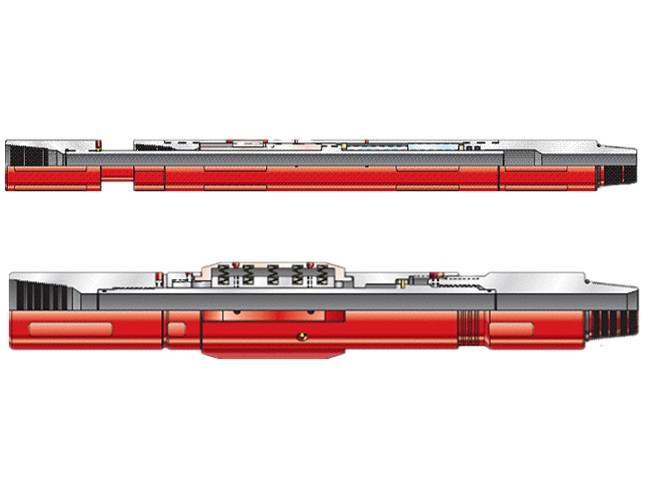

FUTURE-Series Subsurface Safety Valve

Description:

FUTURE series subsurface safety valve is a kind of tubing retrievable safety valve which

is controlled on the surface through hydraulic control line. It directly connects to the

tubing string as paFUTURE of production workstring. After installation, it is operated by the

pressure in control line. While ceFUTUREain amount of hydraulic pressure is applied

through the control line to the safety valve, the valve will be open; while the

pressure is released, the safety valve will be closed and the tubing string is closed

at the same time.

Features:

1. The flapper has pressure equalizing type and non-pressure equalizing type;

2. Locking and sealing structure are designed at the upper side;

3. It is highly reliable to use metal to metal sealing style in the sealing chamber;

4. The upper and bottom thread can be customized according to customers'

requirements.

Designation Model:

FUTURE- FUTURE Series

M- Metal to Metal sealing design

E- Self- equalizing mechanism

S- Slimline Design on Outer Diameter

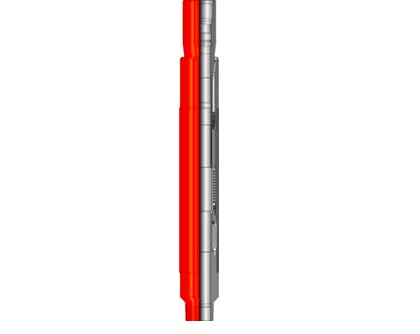

RV-FUTURE-Series Wireline Retrievable Safety Valve (WRSV)

Application:

The RV-FUTURE-series safety valve is a wireline retrievable surface controlled subsurface

safety valve that can be used as alternative method of tubing retrievable safety

valve (TRSV) or as remedial solution when the TRSV is out of work. This safety

valve can work with safety valve landing nipple or other place which can be

communicated with hydraulic system from control line. This WRSV incorporates a

modular design to provide flexibility and adaptability to existing and new

completions. When assembled to a wireline lock, the assembly can be installed

in a safety valve landing nipple. Hydraulic control line connects the safety valve

nipple to provide hydraulic communication with WRSV The close mechanism is

the same as TRSV.

The RV-FUTURE- series WRSV provides customized models for adopting specific Lock

and Profile from customer’s existing or planning safety equipment.

Model Designations:

1. RV-FUTURE - RV-FUTURE-series

2. E - Incorporates self-equalizing system

3. H – High Pressure for 10,000 psi

4. D - For deep set environment

5. Q – High Pressure for up to 15,000 psi

6. S - Slimline design on cuRV-FUTUREed flapper

Safety Valve System

Control Line

Control Line is used to operate and control the subsurface safety valve. The

control line provide by ROCK complies with ASTM specifications with wide

range of metallurgies. Encapsulated control line is also available and

improves the crush and abrasion resistance with various configurations.

Feature/Benefits

Control Line Material: 316SS,316LL, Monel 400, Nickel Alloy 825, Nickel

Alloy 625 and others

Encapsulation Material: High Density Polyethylene, Santoprene, PVC, Halar

and others

3.Model P/FUTURE-3 and P/FUTUREL-3 Hydraulic Set Retainer

Production Packer

Model P/FUTURE-3 and P/FUTUREL-3 Retainer Production Packer are the

hydraulically set version of the Model P/DAB and P/FAB respectively. P/FUTURE

series provide the largest possible bore through ID combined packer and seal

assembly. The P/FUTURE packer is run by connecting an Anchor Seal at above

and it can be set by applying the tubing pressure once it on depth. This

feature is ideal for running the packer in the wellbore with high deviation.

They are the permanent type packers and can only be removed by milling.

Features/Benefits

• Solid and slim construction provide the capacity for fast running in hole

• The packing element resists swab-off

• Two opposed sets of full circle and full strength slips assure the stability

after packer is set

• Expandable metal back up rings creates solid barrier for packing element

extension during setting

• The largest completion ID can be achieved by selecting proper packer and

its seal assembly

• Safety of flanged up completions permits displacing tubing before setting

packer

• No tubing rotation or reciprocation on surface for setting packer

• P/FUTURE-3 series packer are designed for 10k psi working pressure rating

• P/FUTUREL-3 series packer are designed for 7.5k psi working pressure rating

• Optional test fixtures permit high pressure test of anchor seal before running in hole

3.Mechanical Set Retrievable Testing Packer

Model P/M mechanically set retrievable packer is a full opening hookwall packer

for testing, treating and squeeze cement operation. The packer body includes a

J-slot mechanism, mechanical slips and hydraulic slips. The hydraulic holddown

mechanism uses large and heavy duty slips to prevent the packer from

being pumped up the hole. The packer is set by rotating the workstring.

Features and Benefits

• Reliable Setting

• Wide Casing Weight Range

• Hydraulic Hold-Down prevent Packer from being pumped up the hole in High pressure

• Packing element material is available for HNBR an Aflas

• Working with Straddle Packer, Safety Joint and Circulation Valve for completing DST

P/HS Hydraulic Set Retrievable Packer

Model P/HS is a high performance production packer with single string

retrievable, hydraulic set and shear release packer. The P/HS packer

offers features that provide maximum pre-set prevention while running,

improved sealing and retrieving reliability.

The P/HS packer is hydraulically activated by applying tubing pressure

against a plugging device below the packer. The packer requires only

straightly pull to release.

The tubing plugging device must be positioned below the packer for

actuation such as Ball Seat, Hydro-Trip Sub, Sliding Sleeve with Blanking

Plug, Flow Control Landing Nipple with Blank Plug or other hydraulic

setting devices.

Feature and Benefits

• Short and compact design

• Hydraulic interlock system prevents preset while running in hole

• Built-in unloader and bypass – to- aid in releasing and retrieving

• Special packing element design incorporates a zero gap back-up

• Bi-Directional slips

• No mandrel movement during setting allows stacked packer application

• The shear release force can be ordered by client

------------------

GT Dual String Retrievable Packer

Model P/GT is the new packer with high performance dual string

retrievable hydraulic set and shear release packer. The simple and reliable

design incorporates a versatile packing element that is ideal for high

pressure gas condition.

Features and Benefits

• Simply operation, install and retrieve packer no need tubing

manipulation

• Shear release mechanism allows packer to be released by simply

pulling on either tubing string

• Hydraulic interlock system prevents premature set

• Bi-directional slips eliminates the extra leak paths associated with

hydraulic hold-down

• Shear rings improves retrieving reliability and flexibility

• Short and compact design

• No mandrel movement during setting allows stacked packers

applications

--------------

DESP Feed Through Packer

Model P/DESP packer is a short and economic packer designed for Electric

Submersible Pump (ESP) application, the main string is connected with

production tubing, while the second string can be used for feeding through

cable for ESP, the other ports can be used for installing the Gas Vent valve,

chemical injection lines. The solid body configuration eliminates relative

movement between strings during setting.

Features and Benefits

• Short and economical design

• Pressure and temperature rating are 2,500 psi and 300 Deg F

• Hydraulic set and straightly pull shear release

• Multi Ports on the packer can be ordered specially

• Material for packing element: HNBR and Aflas

• The shear force for releasing can be ordered specially

---------

SC-2PT Retrievable Packer

Model P/SC-2PT is a high performance retrievable packer with internal seal

bore. This packer can be set on wireline, slick line or tubing with specially

setting tools which is the same tools used with the Model P/D packer.

Feature and Benefits

• Set with wireline or hydraulic setting tools

• The bottom guides can be ordered specially

• Packer setting permits tubing expansion or contraction

• Easily retrieving due to caged slips and improved releasing mechanism

• Case hardened slips are suitable for all grades of casing include V-150

• Compatible with standard seal assembly, TCP and Gravel Packer system

Anchor Seal Assembly

Anchor Seal Assembly are worked with the permanent production packer

with seal bore, the seal has half mule shoe at bottom and can be

connected with packer directly. It can be released by right hand rotation of

workstring.

Locator Seal Assembly

Locator Seal Assembly is used for permanent production packer with

seal bore or the completion string has seal bore extension at below. The

seal bottom can be half mule shoe or threaded. It run and locate on the

packer after packer is set.

---------------

Flow Control System

Siding Sleeve

The Model FL/R Series Sliding Sleeve Doors are high performance and

equalizing sliding sleeves which provide the communication between the

tubing and annulus for circulation or production. It is one of common down

hole flow control devices in well completion and production. When desired, the

sleeve can be shifted open or closed using standard slickline operations and a

B type shifting tool.

By modular design concepts, they were designed to provide any lock profile

and compatible sealbores can be specified to accept a wide range of slickline

locks and other accessories tools. The sleeve is available with 2 types:

Downshift to Open or Upshift to Open. In some special circumstance, it is

suggested to us Upshift to Open, such as Crude Oil production. Modular

design permits conversion from Downshift to Open to Upshift to Open by only

changing the upper and lower subs.

The body can be designed for several standard materials such as 4140, 9Cr,

13Cr and Nickel Alloy 718 for wide range applications.

Features and Benefits

• Mill Slots design for flow ports on both housing and insert allowing more

flow area and reducing erosion

• The flow area is not less than the tubing ID area with the same size

• Equalizing mechanism equalize the differential pressure before opening to

protect the sealing elements

• Weight indicating on the Close, Equalizing, Open positions

• Provide standard lock profile and sealbore size for flexibility

• The sealing elements can be specially ordered for meeting hostile

downhole environment

--------------

FC/B Shifting Tool

Model FC/B shifting tool is used for opening or closing production sliding

sleeve. It can be used on model XA, XO, XD type. The non-selective release

key on shifting tool can be released from sliding sleeve once the open/close is

done. It can open/close other sleeves again. So this tool can shift all the sliding

sleeve in one trip.

This shifting cannot pass through sleeve with selective profile.

-----------------

FC/F Top No-Go Landing Nipple

The Model FC/F landing nipple is Top No-Go or selective seating nipple and

designed to run in well on the completion tubing to provide a specific landing

location for subsurface flow control equipments, such as blanking plug for

hydraulic packer setting, gauge, check valve, choke and other devices. The

completion can have as many selective nipples with the same ID in any

sequence as desired on the tubing string

-------------

FC/R Bottom No-Go Landing Nipple

The Model FC/R landing nipple is Bottom No-Go seating nipple and designed

for using in single nipple installation or as the bottom nipple in a series

landing nipples. The application of FC/R is the same as FC/F for landing flow

control devices. The bottom no go shoulder can land the lost in hole objects

during production or other operation

--------------

FC/FWG Bypass Blanking Plug

The Model FC/FWG Bypass Blanking Plug is a top no-go wireline retrievable

tubing plug that is designed with a removable mandrel for equalizing pressures.

It can be only set in Model FC/F landing nipple. The removable mandrel is held

in the bypass position by the running tool to allow fluid bypass when landing in

seating nipple. Once the plug is set, the removable mandrel is shifted and lock

to close the bypass port. When retrieving the plug, the mandrel should be

removed at first by standard pulling tool for equalizing pressure.

Running Tools: Model FC/C-1 running tool

Retrieving Tool: Model FC/SB or FC/JDC pulling tool

Accessory Tool: Model FC/B Probe

----------

FC/RZG Bypass Blanking Plug

Model FC/RZG Bypass Blank Plug is bottom no-go wireline retrievable

tubing plug that is designed with a removable mandrel for pressure

equalizing. It can be only set in the Model FC/R seating nipple or profile.

The operation process and setting mechanism is the same as Model

FC/FWG.

Running Tools: Model FC/C-1 running tool

Retrieving Tool: Model FC/SB or FC/JDC pulling tool

Accessory Tool: Model FC/B Probe

--------------------

FC/FWB Instrument Hanger

Model FC/FWB Instrument Hanger is located in the upper most Model

FC/F nipple, to land geophysical instrument for data recording.

Running Tools: Model FC/C-1 running tool

Retrieving Tool: Model FC/SB or FC/JDC pulling tool

Accessory Tool: Model FC/B Probe

-------------------

FC/RZB Instrument Hanger

Model FC/RZB Instrument Hanger is located in the upper most Model

FC/R nipple, to land geophysical instrument for data recording.

Running Tools: Model FC/C-1 running tool

Retrieving Tool: Model FC/SB or FC/JDC pulling tool

Accessory Tool: Model FC/B Probe

---------------

FC/FB-2 Equalizing Check Valve

Model FC/FB-2 equalizing check valve is also called standing valve, which

prevent downward flow which permitting the upward flow. It also can be

used as plug for building pressure. Model FC/FB-2 can only be set in FC/F

profile. The no go shoulder prevent downward movement but the valve are

not locked into the profile to prevent upward movement.

Running Tools: Model FC/C-1 Running Tool

Pulling Tool: Model FC/SB Running and Pulling Tools

--------------------+

FC/RB-2 Equalizing Check Valve

Model FC/RB-2 equalizing check valve is also called standing valve, which

prevent downward flow which permitting the upward flow. It also can be

used as plug for building pressure. Model FC/RB-2 can only be set in

FC/R profile. The no go shoulder prevent downward movement but the

valve are not locked into the profile to prevent upward movement.

Running Tools: Model FC/C-1 Running Tool

Pulling Tool: Model FC/SB Running and Pulling Tools

-----------------

FC/C-1 Running Tool

Model FC/C-1 Running Tool is used for running flow control devices that

have external fishing neck locks such as FC/FWG、FC/RZG、FC/FSG、

FC/FB-2、FC/RB-2.

------------------------

FC/SB Running and Pulling Tool

Model FC/SB Running and Pulling Tool is designed for jobs in which

extensive downward jarring is required. Tools use downward jarring to

release.

------------------

Bridge Plug and Cement Retainer

BP/STWB Wireline Set Bridge Plug

Model BP/STWB Wireline Set Bridge Plug are compact, small OD and

designed for easy drill out. These Bridge Plugs will set securely in all but

the very highest tensile casing. A ratchet lock ring stores the setting force

in the Plug. The one piece packing element and metal back up rings

combine for a superior seal. The case hardened, one piece slips virtually

eliminate premature setting, yet can be easily drilled out. They are

available for 2 3/8” through 20” casing.

Features and Benefits

• Set with standard Baker E-4 wireline setting tool;

• Ratchet lock rings secure dynamic setting force;

• Shear Stubs are Baker style and connect directly to the Baker

Adjuster Sub;

• Crossovers are not required;

• High working pressure up to 10,000 psi;

• Recommended to 300 deg F application for normal packing element,

special material is available for 400 deg F type.

------------------

BP/STMB Mechanical Set Bridge Plug

Model BP/STMB Mechanical Set Bridge Plugs are used to isolate zones for

temporary or permanent abandonment. These drillable Bridge Plugs set

securely in any hardness casing. A ratchet lock ring stores the setting force in

the Bridge Plug. The one piece packing element and metal back up rings

combine for a superior seal. The case hardened, one piece slips virtually

eliminate premature setting, yet can be easily drilled out. They are available for

4 1/2” through 16” casing.

Features and Benefits

• Set with standard Baker mechanical setting tool;

• Ratchet lock rings secure dynamic setting force;

• High working pressure up to 10,000 psi ;

• Recommended to 300 deg F application for normal packing element, special

material is available for 400 deg F type

-----------------------

BP/STWR Wirline Set Cement Retainer

Model BP/STWR Wireline Set Sleeve Valve Cement Retainers are used for

secondary cementing operations. These drillable retainers set securely in any

hardness casing. A ratchet lock ring stores the setting force in the retainer. The

one piece packing element and metal back up rings combine for a superior seal.

The case hardened, one piece slips virtually eliminate premature setting, yet can

be easily drilled out. They are available for 4 1/2” through 20” casing.

Features and Benefits

• Set with standard Baker E-4 wireline setting tool and adapter kits;

• Two trips for setting and squeezing separately;

• Ratchet lock rings secure dynamic setting force;

• High working pressure up to 10,000 psi for size 7” or below;

• Recommended to 300 deg F applications for normal packing element, special

material is available for 400 deg F type.

--------------------

BP/STMR Mechanical Set Cement Retainer

Model BP/STMR Cement Retainers with Sleeve Valve are used for secondary

cementing operations. These drillable retainers set securely in any hardness

casing. A ratchet lock ring stores the setting force in the retainer. The one piece

packing element and metal back up rings combine for a superior seal. The case

hardened, one piece slips virtually eliminate premature setting, yet can be easily

drilled out. They are available for 4 1/2” through 16” casing.

Features and Benefits

• Set with standard mechanical setting tool;

• One trip for setting and squeezing;

• Ratchet lock rings secure dynamic setting force;

• Pressure balanced sleeve valve is operated by tubing manipulation;

• High working pressure up to 10,000 psi for size 7” or below;

• Recommended to 300 deg F application for normal packing element, special

material is available for 400 deg F type

-------------

5.1.1 9-5/8 53.5PPF ESP Packer

5.1.2 9-5/8 53.5PPF ESP Packer

5.1.3 9-5/8 58.4PPF ESP Packer

5.1.4 9-5/8 58.4PPF ESP Packer

5.1.5 9-5/8 61.1PPF ESP Packer

5.1.6 9-5/8 61.1PPF ESP Packer

5.1.7 Penetrators System for ESP Packers Mentioned Above

5.2.1.1 SSD (ABOVE ESP PACKER)

5.2.1.2 Check Valve

5.2.1.3 Check valve Redress kit

5.2.1.4 SSD shifting Tool

5.2.2.1 SSD (BELOW ESP PACKER)

5.2.2.2 Check Valve

5.2.2.3 Check Valve Redress kit

5.2.2.4 SSD shifting Tool

5.2.3.1 F Type TOP NO-GO SEATING NIPPLE

5.2.3.2 Blank Plug

5.2.3.3 Blank Plug Redress kit

5.2.3.4 Running/pulling Tool

5.2.4.1 R Type BOTTOM NO-GO SEATING NIPPLE

5.2.4.2 Blank Plug

5.2.4.3 Blank Plug Redress kit

5.2.4.4 Running/pulling Tool

5.2.5.1 4 1/2" Adjustable Swivel Joint

5.3.1.1 SSD (ABOVE ESP PACKER)

5.3.1.2 Check Valve

5.3.1.3 Check valve Redress kit

5.3.1.4 SSD shifting Tool

5.3.2.1 SSD (BELOW ESP PACKER)

5.3.2.2 Check Valve

5.3.2.3 Check Valve Redress kit

5.3.2.4 SSD shifting Tool

5.3.3.1 F Type TOP NO-GO SEATING NIPPLE

5.3.3.2 Blank Plug

5.3.3.3 Blank Plug Redress kit

5.3.3.4 Running/pulling Tool

5.3.4.1 3 1/2" Adjustable Swivel Joint

"X-Over

(Premium thread : VAGT / Vam top / JFE Bear / others) "

POD/CAN SYSTEM

Pressure test sub

7-5/8" CSG

7-5/8" CSG PUP JTS

7-5/8" CSG PUP JTS

Lift SUB

WORK STABLE

PENETRATOR

Setting Nipple Below POD

Junk Basket for POD (Optional)

Auto Divertion Valve

POD/CAN Gas Vent Integrited into the POD/CAN

POD/CAN Gas Vent Valve Assembly

X-over

……

9-5/8" 53.5PPF Retrievable packer

9-5/8" 58.4PPF Retrievable packer

6-5/8" 28PPF Isolation packer

7" 32PPF Isolation packer

7" 29PPF Isolation packer

5-1/2" 17PPF Isolation packer

Chemical injection sub

Chemical injection sub control line

Chemical injection sub control line

Chemical injection sub control line

Chemical injection skid- surface

Down hole Sensor's stand alone panel

Accessories

……

3-1/2" 9.2 PPF Y-TOOL BLOCK

4-1/2" 12.6 PPF Y-TOOL BLOCK

Telescopic Swivel

By-pass tubing

Wireline entry guide

Blank Plug

Blank Plug running/pulling tool

"LOGGING TOOL SUIT TO ABOVE MENTIONED Y-TOOL

( RECOMMENDATION)"

others …

6 5/8 " Liner POD Related Completion Tool

Tie-back seal assembly

Retrievable Seal Bore Packer 6-5/8" 24 - 28 lb/ft

Seal Bore Extension

1/2 Muleshoe

Snap latch Seal Assembly to suit Retrievable Seal Bore Packer

Liner Top Packer f/ 6-5/8" 24 - 28 lb/ft

Rotating Liner Hanger Hydraulic Set f/ 6-5/8" 24 - 28 lb/ft

O-Ring Seal Sub

Slick Stinger

Float Shoe

Crossover

7 " Liner POD Related Completion Tool

Retrievable Seal Bore Packer 7" 29 - 35 lb/ft

Seal Bore Extension

1/2 Muleshoe

Snap latch Seal Assembly to suit Retrievable Seal Bore Packer

Liner Top Packer f/ 7" 23- 29 lb/ft X 5" 18lb/ft

Rotating Liner Hanger Hydraulic Set f/ 7" 26 - 32 lb/ft X 5" 18 lb/ft

Crossover

Liner Top Packer f/9-5/8" 53.5-58.4 lb/ft x 7" 32 lb/ft

Rotating Liner Hanger Hydraulic Set f/ 9-5/8" 43.5 - 58.4 lb/ft X 7" 32 lb/ft

Crossover

Crossover

Crossover